XMS

In-Line XRF for Industrial Automation

Compact & Rugged

Ready for In-Line Integration

XMS

The Instrument for Automated XRF Measurement

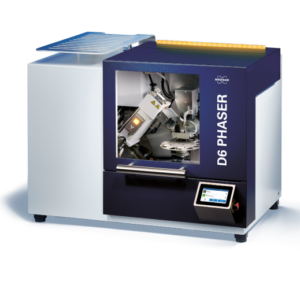

The XMS is a robust and versatile sensor for automated XRF analysis, developed especially to meet the requirements for in-line quality inspection and a range of different industrial applications.

The system's lightweight (< 2 kg) and ruggedized design makes it the perfect XRF analyzer for applications where environmental and operational conditions demand portability, as well as providing an extreme robustness against shocks, vibration, humidity, and dust.

The XMS comes with a dedicated Application Programming Interface based on XML, which allows easy integration into almost any coding languages (Python, C, VB, etc.).

Other features include:

- 20 mm2 SDD with CMOS amplifier and graphene-based window for light element detection

- Patented DetectorShield™ for long term performance and minimal service

- Powerful X-ray source with Rhodium target

- High speed pulse processing electronics for maximum count rates

- Helium flush nozzle for low-energy element detection down to Na

- Splash and dust resistant

Versatile In-Line XRF Analysis

The XMS was designed specifically to bring the benefits of automated XRF measurements to difficult and demanding industrial environments.

The detector is shielded using a graphene-based protective window to prevent punctures and damage whilst still providing optimum performance. When using the optional integrated nozzle for helium purges the XMS can detect down to Sodium, outperforming other available systems used for automated XRF.

In addition, the XMS is portable and versatile. The system has a weight of less than 2 kg allowing it to be easily moved between production lines or transported to in-the-field locations. The compact design of the detector means the detector can be located close to samples in confined spaces, such as core samples in rock sample boxes, or goods that have already been packaged.

СПЕЦИФИКАЦИИ

XMS Specifications

| Technical Specification | |

| XRF Excitation source | Rh target X-ray tube, 5 kV - 50 kV, 5 μA - 200 μA, 4 W |

| Filters | 5 software selectable filters |

| Collimator Options | 8 mm standard, 5 mm or 3 mm optional |

| XRF Detector | State-of-the-art SD detector with Graphene-based window (FWHM resolution < 145 3 eV @ Mn Kα @ 450,000 cps) |

| Detector Shield | Grid to protect against detector punctures |

| XRF Analysis Range | Magnesium to Uranium

Sodium to Uranium (with optional Helium purge) |

| Operating Environment | Operating temperature: -10 °C to +50 °C

Altitude: ≤ 2,500 m Splash/dust resistant enclosure |

| Sample temperature | Default to 150 °C with Ultralene® window

Up to 350 °C with Kapton® window (max. 5 second measurement, min. 60 second cool down) |

| Communication | USB 2.0 (USB-B OTG connection) |

| Software | XML-based communication protocol |

| LEDs | X-RAYS ON, STAND BY and POWER |

| Dimensions | 232 mm x 105 mm x 110 mm (W x D x H) |

| Weight | ~ 1.9 kg |

| Power supply | 9 V DC, 3 A |

| Auxiliary connector | Relay contacts "X-Ray ON", Safety Interlock |